Home

For reasons of the environment and future generations, the Dutch government has aimed to start a transition in short-term to a more sustainable way for the generation of electricity way by utilizing (offshore) wind power. Offshore wind energy conversion will become economical if the costs of energy decreases and the risks for investments are acceptable.

For this, further up scaling of wind turbines towards 10MW is necessary, because of the expensive foundation and installation costs in case of offshore locations. Additionally, due to the low accessibility for offshore locations, it is needed to improve the turbine reliability to achieve a high availability. A higher availability will also result in less urgent maintenance (expensive) and gives improved guarantee of energy production.

As a consequence, the future will be: 'large and efficient built offshore wind turbines, which should be able to produce electrical energy during almost all circumstances and despite of failures'. This project is aimed to contribute significantly to achieve this by means of a more integral approach of turbine operation and the use of more sophisticated turbine control methods.

The approach of 'Sustainable Control' is strongly innovative with respect to ongoing research. 'Sustainable Control' integrates feedback-, safety- and supervising control, which is basically different with respect to the current 'isolated approach'.

Within the scope of wind turbine management, the objective of this project is defined as finding control methods that contribute significantly to the solution of the following specific problems:

- unnecessarily turbine standstill due to 'isolated turbine control approach';

- high costs and upscale limitation due to high turbine loads and stability problems;

- production uncertainty and high loads during extreme (weather) conditions;

- serial damages during shut-down after serious failure detection.

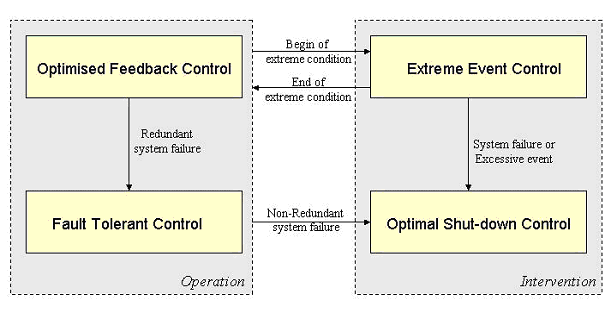

This objective can be realized by the development of the integral approach to manage offshore wind turbines: 'Sustainable Control'. This approach distinguishes four parts, which will be made available as methods if the project has been finished:

- 'Optimised Feedback Control (OFC)', to reduce turbine costs and contribution to further up-scaling of wind turbines by reduction of turbine loads when operating within the design range;

- 'Fault Tolerant Control (FTC)', to avoid unnecessary standstill by the integration of self-adapting control configuration- and detection methods to component degradation;

- 'Extreme Event Control (EEC)', for the reduction of turbine costs and to improve the certainty of power production by decreasing turbine loads during extreme conditions;

- 'Optimal Shutdown Control (OSC)', to avoid serial damages during shut-down after serious failures by condition specific control towards standstill.

The figure below shows a top-level visualisation of 'Sustainable Control':